Press Forming knurling female screw nut

(PF nut)

Heat press-fit knurling female nut production changes

from machining to stamping

←︎M1.2~M3→

Our PF nut contributes a safe,

secure and stable parts production

The heat press-fit female screw nut is usually produced by combination of machine cutting, tapping, and post processing. However, TANGE’s stamping production technology, deploying original built-in progressive die, realises knurling nut production in a single progressive stamping process.

- Our technology overturns the common

sense of nut manufacturing -

Conventional heat press-fit nut; Bar material machining

+ Thread tapping

TANGE’s All in One die building technology + Stamping technology

PF nut; Stamping only!

No post tapping or knurling.

PFインサートナットと従来品の比較

| Conventional cutting nut | PF nut | |

|---|---|---|

| Frange Design |

Limited |

Wide range |

| Quality stability |

Low |

High |

| Environmental load |

High |

Low |

| Processing cost |

High |

Low |

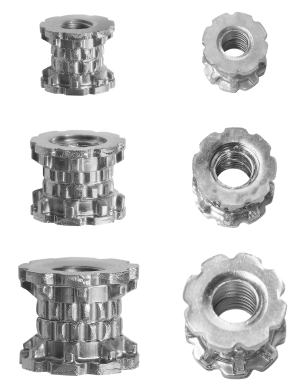

Hard Grip insert female screw nut

(HG nut)

The ideal plastic over mould female screw nut is realised

Our HG nut changes the concept of insert nut.

Conventional insert nuts for heavy duty application was limited due to the strength. TANGE’s Hard Grip insert female nut has realised the ideal strong nut design using stamping production technology.

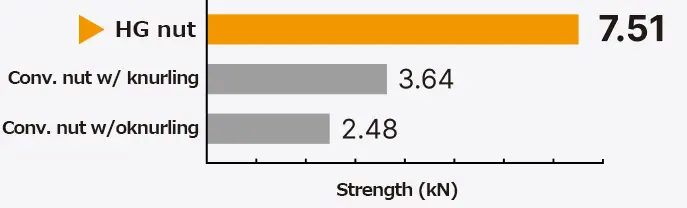

[Tensile test result]

- Sample: M5 nuts with over-moulded with

- glass fibre reinforced polyamide

- Testing parameter: 10 kN, 10 mm/min

[Specification]