We would revolute the screw nut production

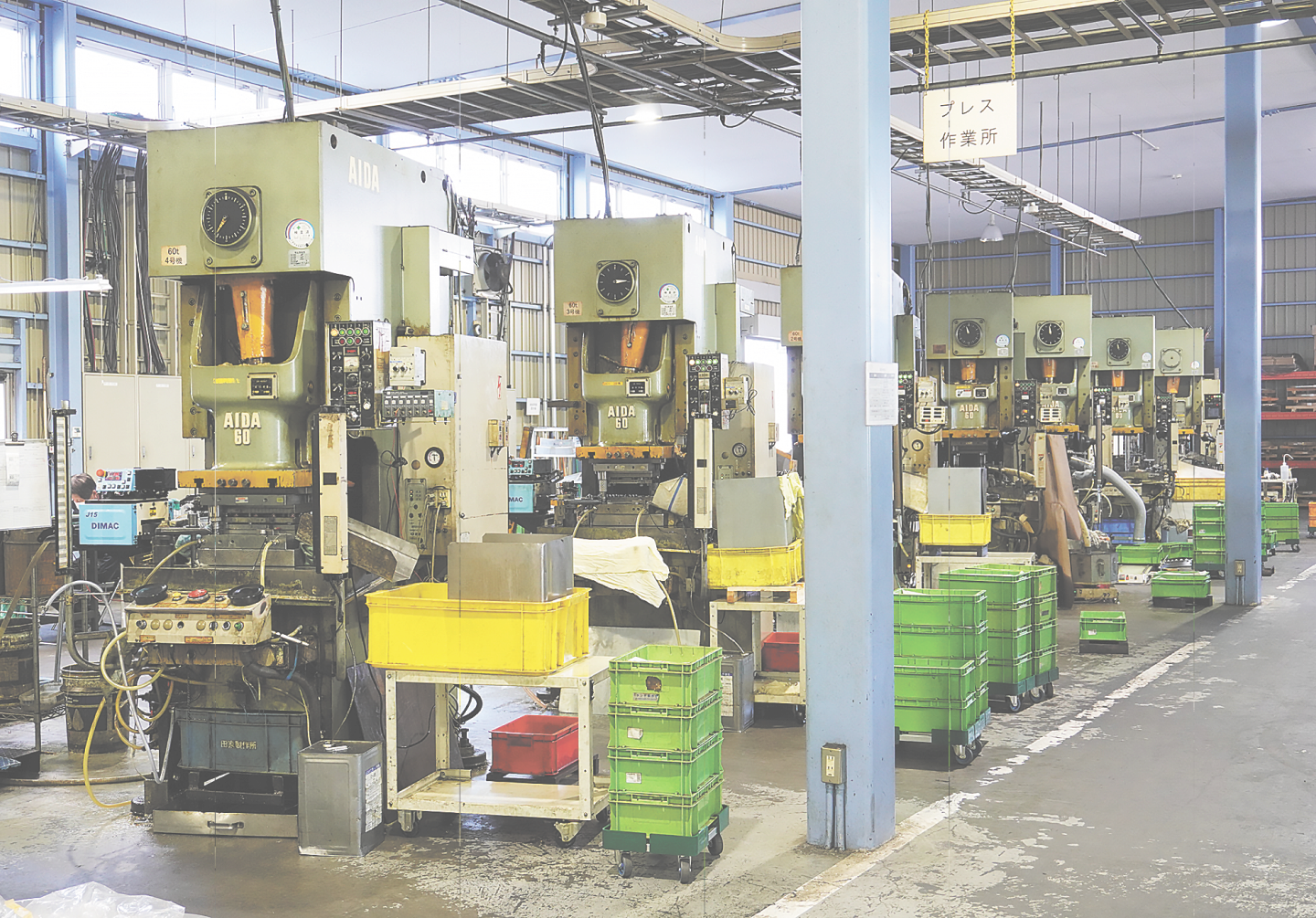

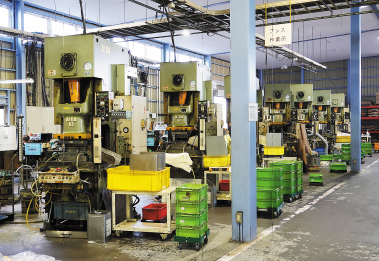

Manufacturing with Monodzukuri pride

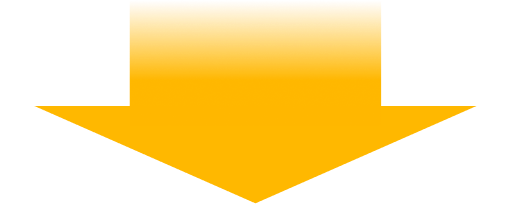

We pursue stamping mould technology development to bring sensation via the stamping parts.

Revolutionising screw nut production is realised

Ultimate screwed part provided by

TANGE’s stamping built-in progressive die

Pressed parts with screws are tapped separately either manually or automatically, by

deploying a tapping machine after stamping. Since the processes are separate, there are issues of quality

stability, e.g. tapping omissions, and production stability, e.g. differences in processing costs and delivery

times according to the production volume.

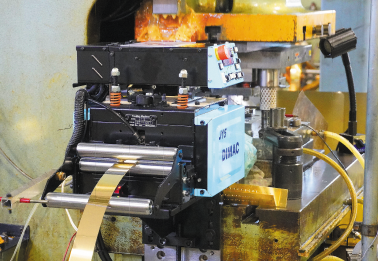

Tange Manufacturing Co., Ltd. (TANGE) has developed an original progressive die with a

built-in tapping device that solves these problems simultaneously. Since our tapping process is

completed during stamping, we are able to manufacture parts with guaranteed superior quality and

consistency. In addition, we also handle knurled parts that apply this built-in progressive die to

mass-produce knurled press parts with guaranteed quality.

This progressive die with a built-in tapping device performs simultaneous compound

processing by combining tapping and knurling area in addition to the conventional stamping processing

areas such as punching, bending, forging, drawing, shaving, and burring. Our built-in progressive die

technology enhances the functionality of the stamping parts while satisfying mass productivity.

TANGE's progressive dies with built-in multi-tasking provide a stable supply of high-quality stamping

parts with high cost performance.

TANGE’s original built-in progressive die technology

-

Tapping and knurling

Tapping and knurling

in stamping process -

- Highly stable quality guaranteed by eliminating additional tapping or knurling separate process.

- Shortest processing time realised by deploying built-in original stamping die.

- Contribute VE while maintain the functions and/or specification.

-

Small as M1.2 tapping

Small as M1.2 tapping

in stable production -

- Highly sophisticated mould system realised from M1.2 to M6 tapping with stable quality.

- Capable to produce max. 6 directions tapping in a part.

- Smaller than 50*50 mm size are applicable.

-

Highly sophisticated

Highly sophisticated

mould unit design -

- TANGE’s original built-in moulds are 100% tooled in-house to maximise the cost efficiency.

- Unit combination progressive die system is deployed, thus short mould tooling ead time is realised.

- Mould unit composed according to our standard to ensure stable production.

Insert/Heat press-fit female screw

-

PF Nut

- Press Forming knurling female screw nut

-

Heat press-fit knurling female nut production changes from machining to stamping

More details

-

HG Nut

- Hard Grip insert female screw nut

-

The ideal plastic over mould female screw nut is realised

More details